Power density features strongly in automotive systems. That can be in more traditional electronic steering and braking or new 48V/12V, hybrid and full electric vehicle (EV) systems. Nexperia’s latest LFPAK88 copper clip package combines small footprint, low RDSon and high ID to achieve power density above 1 W/mm3.

As a major driver in numerous applications across many markets, power density features strongly in automotive systems. The move to dual redundancy to increase system safety in electronic power steering for example, effectively doubles the amount of electronic components but not the space they need to fit into.

With more 48V mild hybrid vehicles now coming on stream we are also seeing the introduction of additional automotive applications to support lower CO2 emissions such as belt-driven starter generators (BSG) and 12/48V DC/DC converters. Somehow these modules must fit within existing space constraints, again emphasising the need for high power density solutions

LFPAK88 really helps in all these situations. Its combination of small footprint, low RDSon and high ID, achieves a power density above 1 W/mm3 – that’s a lot of power packed into into every cubic millimeter! Let’s begin straightaway with a comparison to illustrate the improvement over alternative packages. The table below highlights various products using the same automotive qualified 40 V superjunction technology platform to show the difference coming from the package and not silicon. For the LFPAK88 these include the previous lowest RDSon of 0.7 mΩ and newly released 0.55 mΩ devices.

|

Part number |

Package |

Max ID (A) |

RDSon (mΩ) |

Power density (W/mm³) |

|

| PSMNR55-SSH |

LFPAK88 |

500 |

0.55 |

1.26 |

|

| BUK7S0R5-40H |

LFPAK88 |

500 |

0.55 |

1.26 |

|

|

425 |

0.7 |

1.16 |

||

|

BUK761R2-40H |

D²PAK |

120 |

1.2 |

0.02 |

As can be seen in the table above, not only can we further reduce the RDson but we are able to increase the maximum drain current significantly. When you include the footprint savings, the result is Nexperia can now offer 53x better power density with the automotive BUK7S0R5-40H and industrial PSMNR55-SSH (compared with 48x previously seen) with the LFPAK88 than is possible with a 3-pin D²PAK. It’s maybe worth noting that due to the clear benefit seen with LFPAK88, the D²PAK BUK761R2-40H was developed but not released.

How is this higher power density achieved? Overall, it results from a combination of innovative package technology and improved silicon technology. Considering the LFPAK88 package itself, there are three factors relating to improved power density:

- higher current capability to increase power

- smaller package outline to increase density

- higher efficiency to reduce thermal issues.

Let me briefly touch on each one in turn.

Clips vs wires – overcoming current connections

The connecting wires between silicon and package terminals of D²PAK and its variants limit the amount of current that can be handled. Whereas the clip bond technology used for LFPAK provides large area contact between silicon and terminals, enabling significantly larger currents to increase output power capability.

Shrinking outline

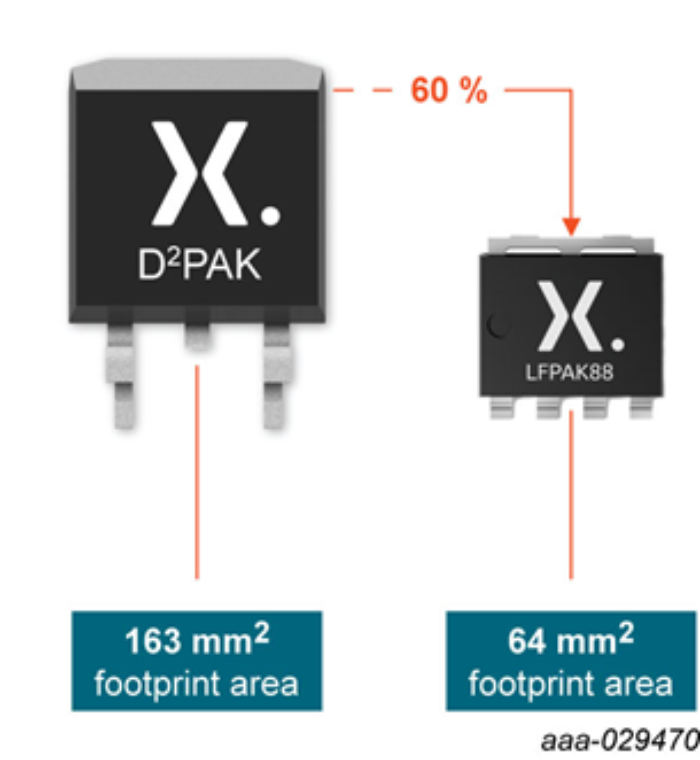

The LFPAK88 package outline was chosen as the best compromise between package current, thermal capability and footprint area for higher power applications. Smaller than the older D²PAK and D²PAK-7 in terms of length, width and height, its 8.0 x 8.0 x 1.6 mm dimensions reduce footprint by 60% compared to D2PAK, and an overall space reduction of 86%.

Keeping it cool with higher efficiency

Operating higher currents in a smaller area makes efficiency crucial, so ‘you don’t have to deal with heat you don’t generate’. High efficiency means more useful power is transmitted to the task in hand. With the LFPAK this is realized through improved RDSon, as the copper clip does not add to resistance, unlike internal bond wires. No bond wires to the source, plus small external source leads, also reduce parasitic source induction. I will go into more detail on parasitic source induction and thermal efficiency in later blogs.

Silicon support

Newer silicon technologies also help to improve power density. Nexperia’s automotive qualified superjunction technology includes narrower cell pitches that reduce package RDSon. This enables higher efficiency and more IDmax capability.

The story to date…

Improving power density continues to be a crucial factor in product design. To this end, the new copper clip LFPAK88 package and superjunction silicon technology combine to deliver excellent power density performance. In the initial release, Nexperia introduced a 0.7 mΩ @ 40 V part (BUK7S0R7-40H) capable of handling 425 A. Now with the new release of 0.55 mΩ parts (BUK7S0R5-40H and PSMNR55-40SSH) that has been measured at 500 A.

The release of the new 0.55 mΩ devices not only delivers a benefit in terms of power density, but also opens up new applications within the car. From existing battery protection devices to new replacements of fuses or relays for reliability reasons, the need for such low RDSon devices is becoming more and more important.