High power density systems are becoming increasingly standard across a wide range of industrial and automotive applications. That has increased demand for components capable of delivering high output power and operating between 600 V and 1200 V. With the CFP40 and CFP60 packages, Nexperia will extend the capabilities of our copper clip technology to high-power diodes and rectifiers.

From the perspective of housing power diodes in this range, that has been the domain of traditional power packages such as DPAK and D2PAK along with the leaded TO-220 / TO-247. However, to improve system efficiency and better dissipate heat away from the component and into the circuit board, and get rid of the extra heatsinks needed for through-hole package assembly, we have seen increased demand to move towards smaller SMD packages that can offer better thermal performance.

The copper clip specialists

As one of the leading innovators in copper clip packaging, Nexperia already offers a large and continuously growing range of options. The technology draws on our proven LFPAK, first launched some 20 years ago, which has also contributed to the development of our new CCPAK for Nexperia’s Gallium Nitride (GaN) FETs (CCPAK: copper clip comes to high voltage applications). For power diodes and rectifiers our Copper-clip FlatPower portfolio (CFP3, CFP5 and CFP15B) covers a wide range of Schottky and Fast recovery devices as well as our new Silicon Germanium (SiGe) rectifiers.

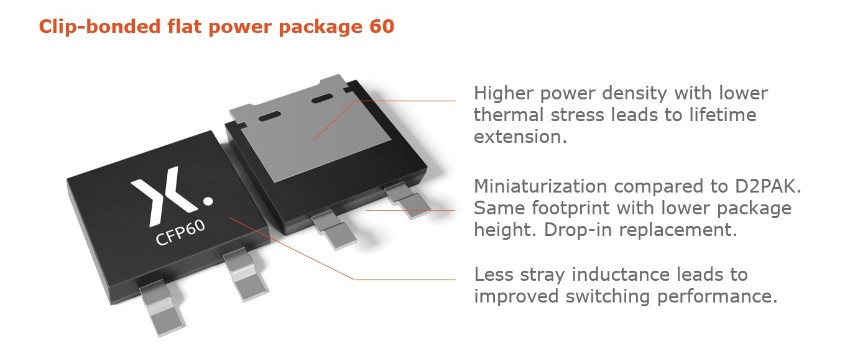

To extend the benefits of our copper clip technology to high-power diodes and rectifiers, Nexperia is investing in the development of new packages, including the CFP40 and CFP60. The benefits of these new packages will include lower parasitic inductances compared to their wire-bonded DPAK and D²PAK alternatives, to improve switching performance along with greater ruggedness and surge current capability, in addition to the reduction of package height.

Top-side cooling for enhanced thermal performance

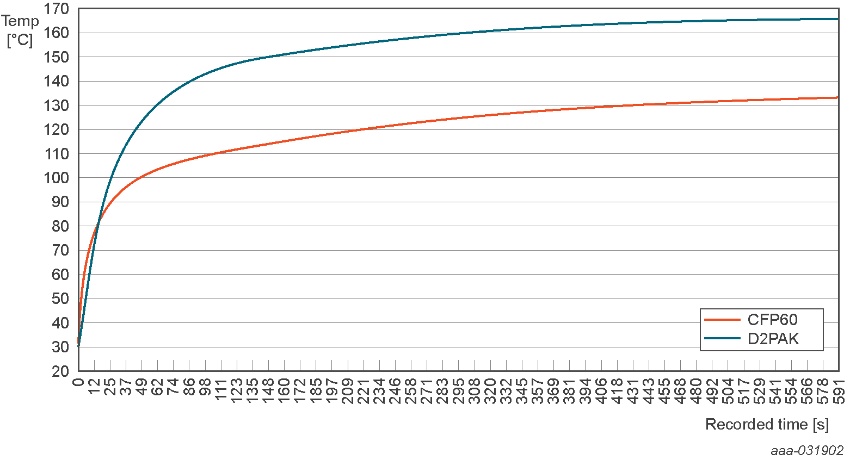

One of the critical challenges for higher power density design is to dissipate heat quickly and safely away from the chip, and into the PCB. With the CFP40 and CFP60, Nexperia will have a package option that effectively offers state-of-the-art thermal performance in a significantly smaller and thinner form factor than their wire-bonded counterparts. When combined with top-side cooling, and compared to the D²PAK, the CFP60 delivers a much cooler case temperature for a given power generated within the chip. Or, turning it around, the CFP60 can dissipate significantly more power for the same case temperature.

Pushing automotive qualification

As with the majority of Nexperia’s portfolio for use in automotive applications, we continue to push the boundaries of compliance testing. And the CFP40 and CFP60 will not be exceptions. For many of the tests we consistently target 2x AEC-Q101 compliance, with many customers looking for more than 1000 hours of testing.