Silicon Germanium (SiGe) rectifiers combine the efficiency of Schottky rectifiers with the thermal stability of fast recovery diodes, enabling engineers to optimize their 100-200 V power designs for higher efficiency. The devices target applications in automotive, server markets and communications infrastructure. By offering an extended safe-operating area with no thermal runaway up to 175 °C, our AEC-Q101 compliant SiGe rectifiers are particularly suitable for high ambient temperature applications.

Previously when designing rectifier circuits in the 100-200 V range, engineers had to compromise between efficiency and operating temperature. While Schottky rectifiers offer very high efficiency, they experience thermal runaway after a certain temperature threshold. So, they offer limited suitability for power circuits in Engine Control Units (ECU) or fuel-injection systems for example, which routinely see temperatures above 150 °C. The alternative is to use Fast Recovery rectifiers. These are extremely thermally stable, but they do have a very high forward voltage and therefore low efficiency.

As car manufacturers and designers of other systems operating at higher temperatures push ever-harder for increased efficiency – whether for miniaturization, performance, regulatory or other reasons – clearly a new solution is needed. As we see with other power semiconductor solutions, bulk silicon devices struggle to offer the required performance and thermal stability demanded by some of today’s high-performance electronic systems. What is needed is a novel technology for cutting-edge high efficiency, thermal stability and space-savings.

SiGe and ideal rectifier performance

SiGe technology has a smaller band-gap, a faster switching frequency and higher intrinsic charge carrier density than silicon. That brings an advantage in high-frequency switching behaviour which is why it has been employed in radio-frequency transistors within ICs for some time. But until now, SiGe diodes have only been the subject of university papers.

Nexperia has been developing SiGe rectifier technology for a few years and we already have several patents on the process that address the apparently conflicting demands for high efficiency and high-temperature operation. But like other major technology innovations, we only release proven scalable technology to the market with an understanding of where and how it can add real benefits to our customers’ designs.

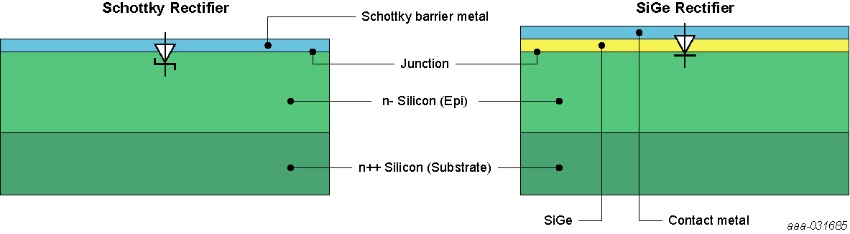

Figure 1 is a simplified diagram of the internal structure of the Nexperia’s new SiGe rectifiers. To further enhance the performance of these SiGe rectifiers, they are housed in our two--pin Clip-bonded FlatPower (CFP) packages (CFP3 and CFP5), which themselves offer excellent thermal dissipation. It also enables pin-for-pin compatibility and drop-in replacements for Schottky and fast recovery rectifiers.

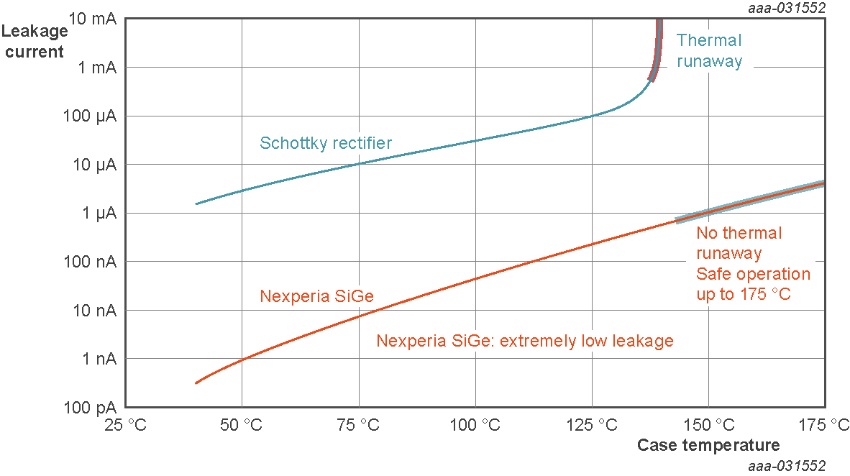

As Figure 2 shows, the new devices retain a high thermal stability, extending the Safe Operating Area – in this example from 145 °C, the temperature at which Schottky rectifiers start to go into thermal runaway. However, our SiGe rectifiers remain stable at up to and beyond 175 °C, the specified limit of the CFP package.

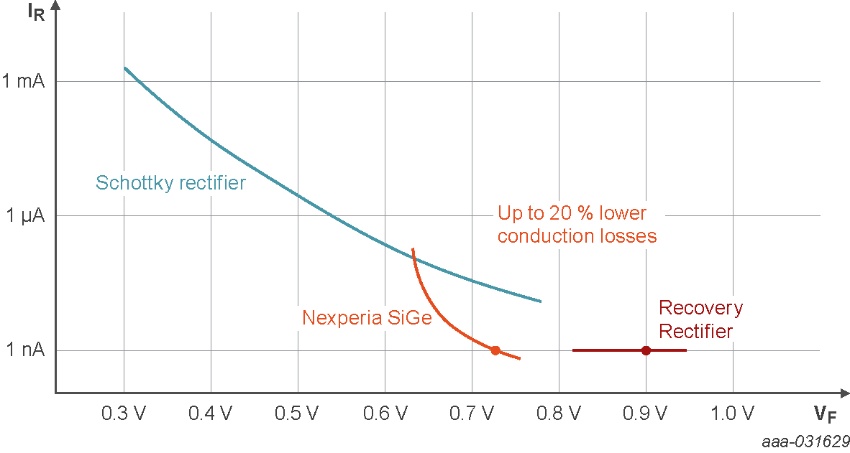

To address efficiency, in Figure 3 we see that typically a Fast Recovery rectifier has a forward voltage of about 0.9 V. Nexperia’s first SiGe diode currently has lowest leakage current (1 nA) of the family, which as the curve shows equates to a forward voltage of around 0.75 V, and an advantage of 150 mV. The result is a reduction in conduction losses of around 20%. How this translates into efficiency is dependent on multiple factors, most significantly the duty cycle of the application. As a rough estimate, a 5 to 10 % efficiency increase could be expected with the same thermal stability as the best fast recovery diodes.

The start of a new family

With any new technology that appears to promise to solve a design challenge, once the technical aspects have been addressed the next concern is, “How easy is it to use?” Although SiGe is a new ‘chemistry’ for rectifiers there are no technological constraints to using SiGe rectifiers. In fact, in some cases our SiGe rectifiers are essentially drop-in replacements for Schottky diodes. Equally, there are no production issues, with Nexperia processing standard silicon wafers in the company’s front-end fabrication facilities in Hamburg.

The new SiGe rectifiers perfectly complement Nexperia’s power diodes offering which currently includes more than 100 Schottky and fast recovery rectifiers in CFP packages, and continues to grow. The first four 120 V SiGe rectifiers are already available, with eight further devices rated to either 150 V or 200 V to be released in the coming weeks. All devices are qualified to AEC-Q101 for automotive use – they even pass 2x AEC-Q101 testing for lifetime as demanded by several car manufacturers. Other significant mass-market applications envisioned for the SiGe rectifiers include LED lighting and communications infrastructure.