Given the unique operating conditions found in automotive electronics, thermal runaway can quickly become an issue especially with Schottky rectifier diodes. Nexperia’s clip-bonded FlatPower (CFP) packaged Schottky portfolio offers the most efficient solutions to address thermal runaway while still providing space and height savings.

We all know that when it comes to realizing the ideal rectifier in real-life, compromises must be made. In the earlier blog, ‘Why Trench Schottky rectifiers are the preferred choice’, we touched on how these diodes deliver a better trade-off between forward voltage drop and the leakage current. We also mentioned that they also offered greater robustness against thermal runaway effects. A potential problem in Schottky rectifier diodes, but one that can be mitigated with proper consideration.

Why thermal runaway can be an issue

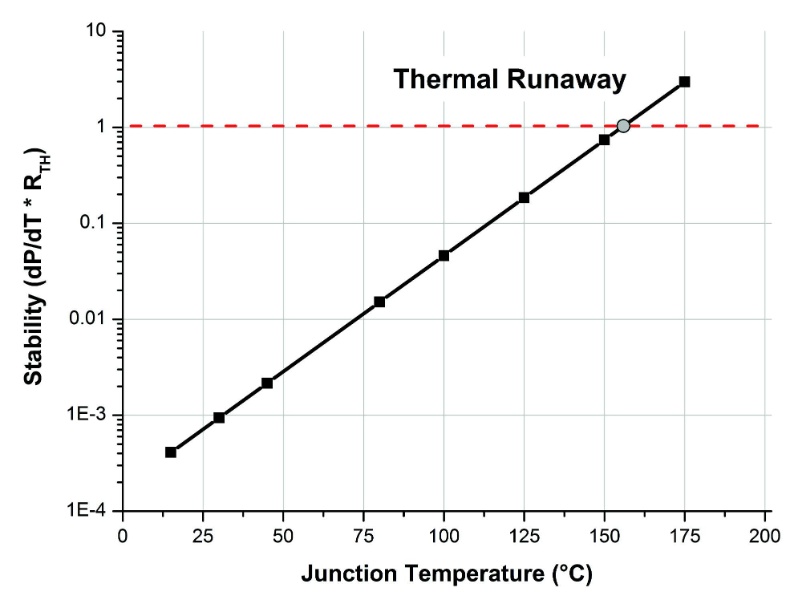

Thermal runaway starts with heat generated by the leakage current of the rectifier. When not managed, this heat causes the junction temperature to rise faster than the thermal system can remove it. Once the heat rises above a critical temperature, the system becomes thermally unstable and the device can fail. This generally occurs when the reverse power losses generated within the diode exceed the power dissipated by the package.

While many factors are at play, generating unnecessary heat and not removing heat fast enough are two key issues. This is why thermal runaway tends to happen more often in applications with ambient temperatures of 100 °C and higher. In these situations dissipating excess heat can be difficult. Typical examples include under-the-hood automotive applications and LED lighting, where the heat from the LEDs is dissipated close to or on the same heat sink as the drive electronics.

CFP – a thermally optimized package

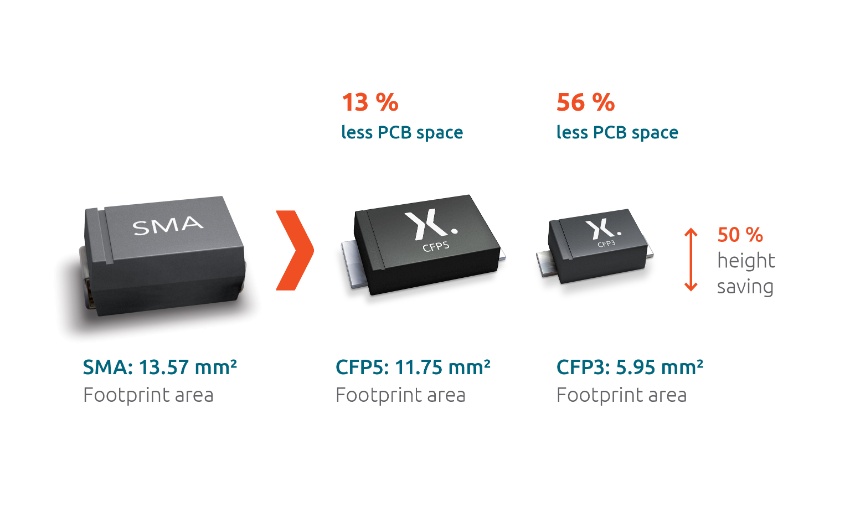

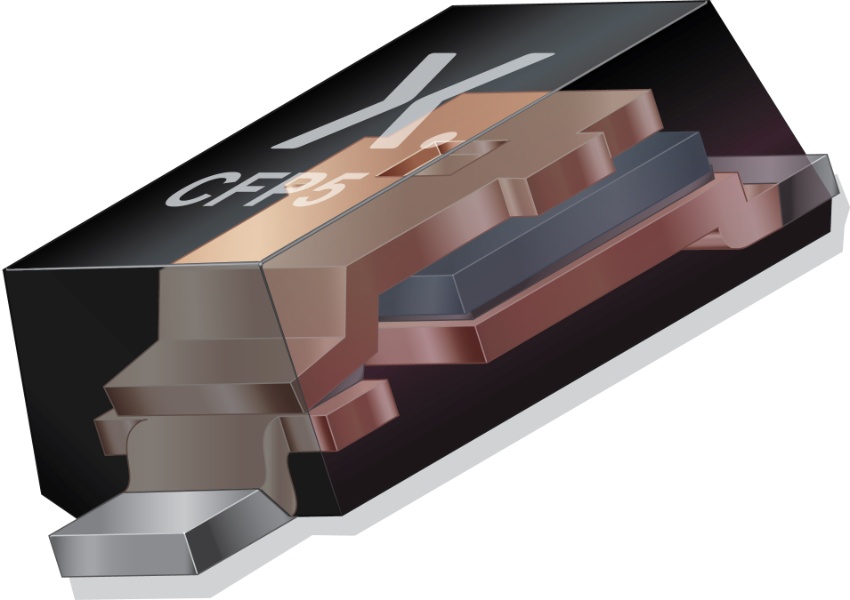

Naturally using a thermally optimized package that ensures efficient heat transfer into the heatsink helps keep junction temperature under control. The key here is to reduce thermal resistance. By using a solid copper clip in contact with the die, Nexperia’s CFP package design helps curtail thermal runaway. It delivers a thermal performance on par with traditional surface-mount designs such as SMA and SMB, while offering significant footprint and height savings. The design also has the advantage of reduced electrical resistance and package inductance.

The right choice for the right application

While an optimized thermal package addresses some of the challenges, there is no one-solution-fits-all approach to solve and improve thermal runaway in Schottky diodes. The best solution often varies by application and solving thermal runaway includes careful component choices and component package selection.

For example, with planar diodes a lower forward voltage drop generally comes at the price of an increased leakage current and higher reverse power losses. And while a Trench Schottky rectifier has a wider safe operating area, given its thin dielectric structure it may not be the best option for designs sensitive to parasitic capacitance.

That’s why Nexperia offers both our planar and trench Schottky diodes in efficient CFP package options including the CFP3, CFP5 and CFP15(B). Rated to a junction temperature of 175 °C, these AEC-Q101 qualified packages can move a diode out of the thermal runaway danger zone. And we can help our customers select the right Schottky rectifier diode and avoid thermal runaway in their application.