When it comes to any system, to achieve the most efficient design we try to utilize the most ideal solution possible. Compared to their planar counterparts, Trench Schottky rectifiers take us much closer to that ideal solution.

We are continually pushing our electronic systems to be ever more efficient. For many systems and specifically power conversion circuits, the planar Schottky barrier diode has been a design mainstay for a long time. However, planar diodes impose a trade-off in key performance characteristics such as forward voltage drop and leakage current. Similarly, in high frequency applications, traditional Schottky diodes are far from the ideal lossless and instantaneous rectifier solution we would love to use.

The ideal rectifier

An ideal rectifier should have a low forward voltage drop, a high reverse blocking voltage, zero leakage current and low parasitic capacitance. But when it comes to realizing this in real-life, compromises must be made.

For example, certain metals can be used to minimize the voltage drop across the metal-semiconductor interface but only at the expense of a higher leakage current. Or if the drift region is made thicker to achieve a higher reverse blocking voltage, then the advantage of a low voltage drop across the junction can disappear. Traditionally, this has limited the reverse blocking voltage of Schottky rectifiers to well below 200 V.

Etching trenches into silicon

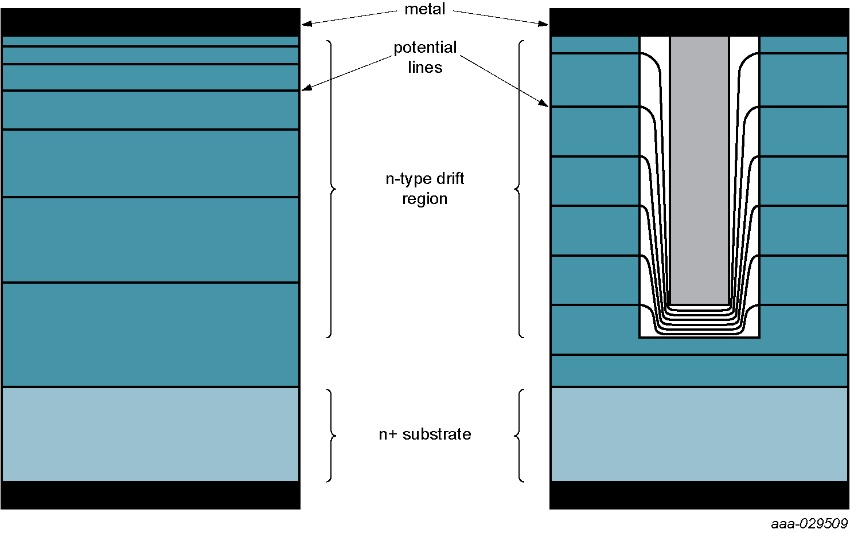

One challenge then is to increase reverse voltage without increasing leakage current. A limitation of a planar Schottky is that the equi-potential lines tend to be crowded close to the metal electrode and not the substrate, which can lead to early breakdown when the critical electrical field is exceeded near the surface. By etching trenches into the silicon and filling them with polysilicon, effectively depletes the drift region in the reverse direction and flattens the electrical field profile along the drift region.

That means our Trench Schottky rectifier family achieves a well-balanced trade-off between Vf and IR. Compared to equivalent planar diodes, the Trench devices have a wider safe operating area. With robustness against thermal runaway, this makes them ideal in applications which experience higher ambient temperatures.

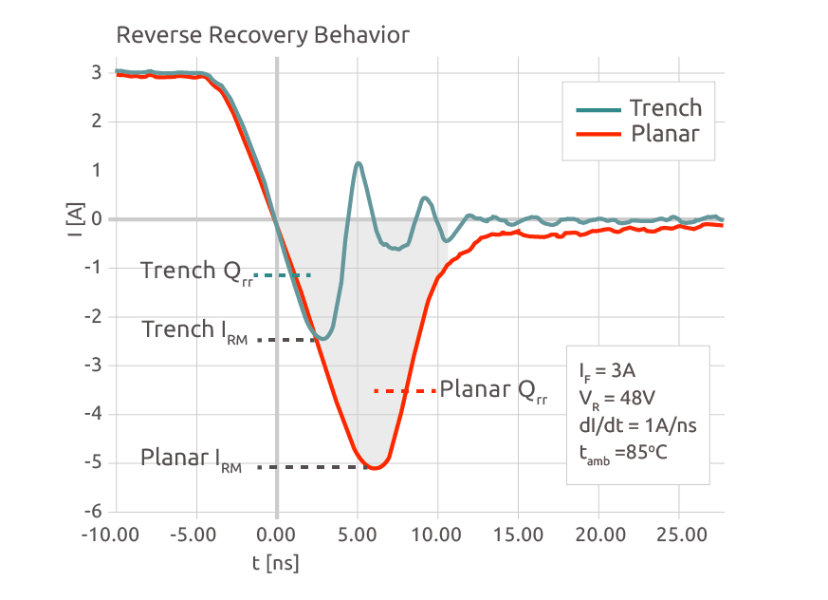

Despite stating a higher parasitic capacitance in the data sheet, the Trench Schottky rectifier provides another benefit. Due to its higher current density it has a smaller effective junction capacitance compared to planar Schottky diodes. Therefore, Trench rectifiers have much less stored charges (Qrr) and are the right choice for high frequency applications. A comparison of reverse recovery behavior of a Trench Schottky diode to its planar counterpart is shown below.

The Trench Schottky diode has much less Qrr compared to the planar Schottky. This results in lower switching losses when used in a switch-mode converter circuitry. EMI measurements revealed that the observed “ringing” of the Trench Schottky does not affect the electromagnetic emission levels.

All-in-all, Trench Schottky rectifiers are the preferred choice

By combining Schottky with Trench technology, the latest Trench Schottky rectifiers bring the performance benefits many applications demand. Trench Schottky diodes deliver a better trade-off between forward voltage drop and the leakage current. They also have excellent switching performance together with robustness against thermal runaway effects.

Nexperia Trench Schottky devices are designed with a main focus of attention on their thermal stability and robustness against thermal runaway, resulting in a wide safe operating area. For designers looking for even more thermal robustness, which may be necessary for applications in very harsh environments such as in the high power density automotive domain, then the Trench Schottky rectifier might reach its thermal limits. In those circumstances it makes sense to consider the new SiGe rectifiers from Nexperia.