When it comes to energy efficiency in our homes and offices, a critical component is the main control unit for our heating and cooling systems: the thermostat. Of course, over the years this humble device has undergone quite a dramatic transformation. Gone are simple, inaccurate and manual controllers. Now we have smart thermostats capable of learning, remembering and adjusting to how, when and where you use your system. To further increase system efficiency without losing protection, designers are also replacing mechanical contacts and electro-mechanical relays with enhanced Safe Operating Area (SOA) MOSFETs.

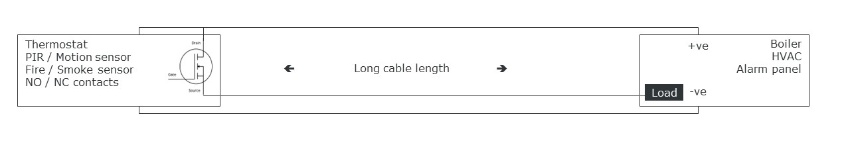

Today’s thermostats offer a host of functions and features to make our homes and offices more energy efficient. Look online and you’ll find a range of smart thermostats, that not only control the temperature, humidity and air quality, but come with features such as scheduling, geofencing, “Eco” modes, even built-in speakers. Often these systems include Wi-Fi connectivity for remote access and to wirelessly connect to other remote sensors in the building. However, when it comes to the connection to the boiler, AC (air conditioning) unit or even the alarm system, these still require a relatively long hardwired cable link.

Due to the electrical loads involved in typical applications, where more sophisticated control is required thermostats have moved from using basic mechanical contacts to electro-mechanical relay switches. Robust and cost-effective, relays can withstand short-circuit current during fault conditions, inductive spikes at switch-OFF and capacitive inrush current during power-ON. They can also handle continuous load currents of several amps.

MOSFETs as a relay replacement

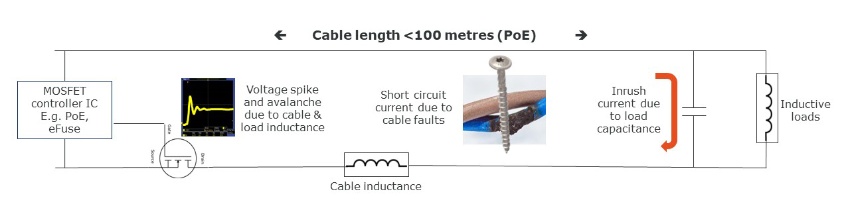

However, as MOSFET technology has evolved, designers are increasingly reaching for MOSFETs to replace electro-mechanical relays and offer substantial footprint savings. For smart thermostats as well as other interlinked sensors and devices, MOSFETs can also provide inrush current limiting and eFuse shutdown capabilities to safely manage overload conditions and fault conditions, for example due to cable faults.

When you take a closer look at the operating conditions for the hardwired connections from the thermostat to the boiler, in many ways the design challenges are very similar to those found in Power over Ethernet (PoE) systems. Drawing on the enhanced SOA characteristics of our Power MOSFET technology, Nexperia has a long heritage of supplying MOSFET devices for PoE applications (as well as hotswap). So, we understand that as designers push the boundaries of application performance it is increasingly crucial to optimize a set of MOSFET parameters to best match their specific application requirements.

Robust and compact

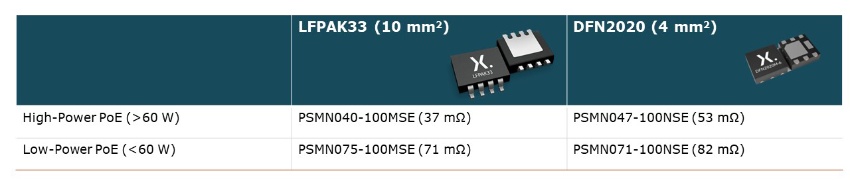

An ASFET (Application Specific MOSFET) is simply a MOSFET that has been optimised for a particular application. In this case, Nexperia ASFETs for PoE, eFuse and relay replacement have been optimised for the strongest SOA and offer 2 to 3 times stronger SOA compared to MOSFETs with similar RDS(on). Originally launched in the compact 3x3 mm LFPAK33 package, they deliver reliable inrush control, robust turn-off during fault conditions, low RDS(on) and high ID(max).

For less demanding applications, such as smart thermostats, compact size is often a high priority. To address this Nexperia has expanded the family into the DFN2020M-6 power package. Delivering a 60% smaller footprint while still providing best-in-class SOA performance for the 4 mm² footprint. Giving designers of even the most compact, feature-rich, smart thermostats, the confidence their product is always protected.

To discover more about our 100 V, standard level ASFETs with enhanced SOA in DFN2020, check out the 53 mΩ PSMN047-100NSE and 82 mΩ PSMN071-100NSE.