Ambient energy harvesting has often been proposed for recharging batteries in remote internet-of-things devices but hasn’t yet taken off. This blog considers the reasons for this before presenting an innovative power management integrated circuit (PMIC) from Nexperia, which will radically improve the viability of energy harvesting with significant benefits for the environment.

Battery replacement doesn’t make sense for many remote IoT devices

The use case for many portable or remotely located devices like IoT environmental sensors, smart tags, and Electronic Shelf Labels ultimately has a cost the end customer must bear, primarily attributable to battery replacement.

In large systems with hundreds or thousands of sensors or ESLs, workforce and material costs are associated with appropriately replacing, recycling, or disposing of dead batteries. This has negatively impacted the adoption of such technologies. In response, to minimize the number of battery changes, users have had no option but to accept lower performance levels from these devices. For example, a factory or smart building operator might program a sensor to provide an ambient temperature reading only once every hour instead of on a more regular basis to maximize the time the device spends in sleep mode, which helps to minimize the drain on the battery. However, compromising performance is unacceptable in other portable applications, like a television remote control, which inevitably requires several battery changes over its usable life.

In addition, improper disposal of batteries has severe environmental implications. For example, in the European Union, data from Eurostat (Waste statistics - recycling of batteries and accumulators," January 2023) shows that approximately 229,000 tonnes of portable batteries and accumulators were sold in 2020, while only about 99,000 tonnes were collected for recycling. These devices produce a significant amount of hazardous waste, usually disposed of in harmful landfills, posing a threat to the environment.

Energy harvesting incumbents are unviable due to inherent shortcomings

Energy harvesting has the potential to overcome these limitations by collecting ambient energy and using it to power electronic devices. Applications where more energy is harvested than consumed can become completely energy-autonomous, but until now, two main factors have limited its application. The first relates to the large size and associated high bill of materials of incumbent offerings. These use a DC-DC converter with a bulky and expensive inductor which is problematic because the form factor of many IoT devices can’t accommodate inductive switching converters. Secondly, due to the variable nature of ambient energy sources (e.g., fluctuating light intensity), these solutions require significant customization to achieve optimum power conversion efficiency, meaning their application is not trivial.

Nexperia’s energy harvesting PMIC reduces board area by up to 20x

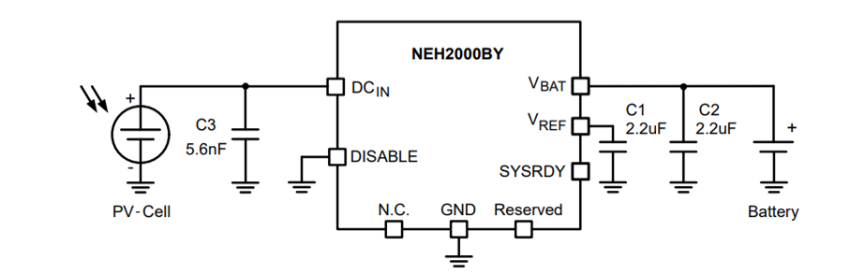

Figure 2 shows Nexperia’s NEH2000BY high-performance PMIC, which can recharge a battery using energy harvested from ambient sources. This PMIC is optimized for photovoltaic (PV) harvesters but integrates with any other harvester that complies with its input voltage range. For a specific application, the NEH2000BY uses an adaptive algorithm to optimize how it transfers harvested energy to the battery. This makes it feasible for designers to develop IoT devices that do not require a battery change during their lifetime without compromising performance.

Another notable benefit of this unique design is that it uses only three tiny external capacitors, not an inductor. This dramatically simplifies PCB design while significantly reducing board size and the overall BOM - the total assembly area is only 12mm². In addition, this enables more straightforward energy harvesting designs up to 20x smaller (than existing solutions) and does not require manual optimization for individual applications.

Maximum Power Point Tracking algorithm adapts to every application

To achieve the highest conversion efficiency, power converters used in energy harvesting systems must be able to adapt as the ambient energy source fluctuates. This means the amount of energy harvested daily is primarily driven by how fast it can find the best power conversion configuration. The NEH2000BY operates autonomously without pre-programming and performs Maximum Power Point Tracking (MPPT) to achieve an optimum average conversion efficiency of up to 80%. This unique MPPT algorithm combines speed with accuracy, allowing the PMIC to adapt to environmental changes in less than a second. This is significantly faster than any currently available solution and maximizes the energy harvested over a day, vastly expanding the number of application areas.

Significant benefits for the environment

The NEH2000BY can economically harvest energy from various ambient energy sources in applications consuming up to several milliwatts hour of power, including wireless IoT nodes, wearable smart tags, and electronic shelf labels. In addition, eliminating the requirement to change batteries in these applications will significantly reduce the amount of hazardous waste produced, with enormous environmental benefits. The NEH2000BY is available in a 16-lead, 3 mm × 3 mm QFN package, operates between -40°C and +85°C and promises to revolutionize energy harvesting in remote IoT devices.