As the industry demands more space savings, power density and current handling capabilities, Nexperia’s latest copper clip package delivers significant improvements. Combining low RDSon and high ID, the LFPAK88 sets the benchmark for power density to over 1 W/mm3.

When it comes to power MOSFETs for a long time the automotive industry has been reliant on older and larger wirebond packages such as the DPAK (SOT428) and D2PAK (SOT404). This began to change in 2004 following the introduction of Nexperia’s copper clip LFPAK package. Suddenly we had a robust SO8 footprint that delivered significant efficiency and performance benefits.

With the release of the LFPAK88, we now have an 8 x 8 mm package option that delivers all the performance enhancements of copper clip with the additional benefits of a larger die size, while still offering significant space savings. Just as the LFPAK56 (SOT669) was designed to provide an efficient replacement to the DPAK, the LFPAK88 (SOT1235) has been designed as an alternative to the larger D²PAK and D²PAK-7 packages.

Current capability

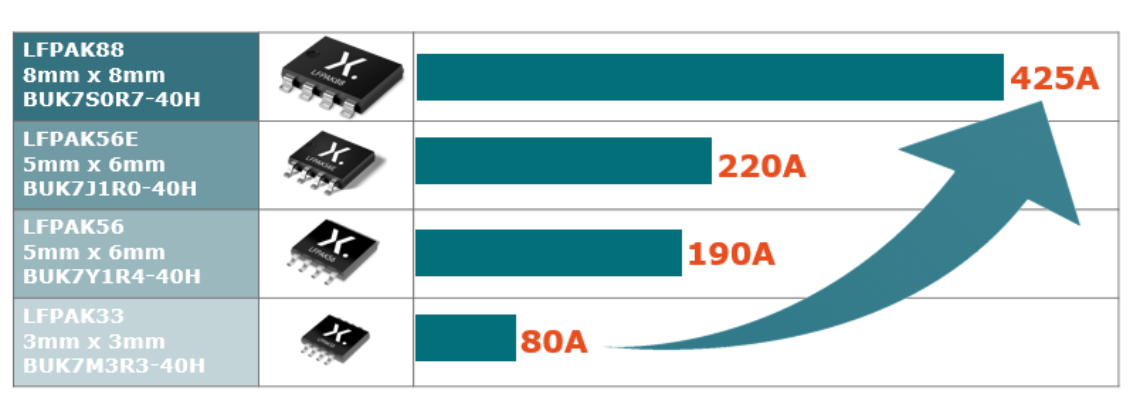

The larger the package, the bigger the MOSFET die that can be used. The larger the MOSFET die, the more current can be efficiently pushed through. And given P = I2R, more current equals more power. With the LFPAK88, Nexperia can now deliver an enhanced range of footprint, current and power options to meet a whole range of system specifications while addressing space concerns.

Below is the example of the best current capability we offer today in our various LFPAK packages using our latest automotive qualified 40 V superjunction technology. With only a slight increase in overall footprint we can offer a significant increase in current capability.

The D²PAK alternative

With the release of the larger LFPAK88 using our copper clip technology and rugged LFPAK platform we expect it will become the de-facto standard for a range of applications. Ultimately replacing the larger D²PAK and D²PAK-7 wirebond packages in applications such as power steering, anti-lock brakes, etc.

Over the next few weeks, I’ll go into more depth on a few topics that highlight how the combination of our 40 V automotive superjunction silicon and LFPAK88 is already helping engineers rethink their designs. The next post will take a closer look at how we achieve power density above 1 W/mm3. Then we will address how the switching efficiency of a short leaded copper clip package minimizes parasitic source inductance before digging into thermal performance and why the much smaller LFPAK88 can be as good as the much larger D²PAK. Finally, we look at how the years of experience Nexperia has in LFPAK and silicon manufacturing is enabling the highest quality standards and performance, well in excess of automotive AEC-Q101 standards.