Every academic year for the past four years, a new team of student engineers, programmers and project managers have taken up the RoboTeam Twente challenge to design and build a squad of robots capable of challenging in the Small Size League of the RoboCup tournament. For 2019-2020, the team started on an ambitious complete redesign only to see RoboCup 2020 in France postponed to 2021. Although a major set-back, it hasn’t stopped the team from completing their redesign.

As part of RoboCup qualification, teams cannot simply fix errors and shortcomings of the existing robots but must innovate and improve the robots and their behaviour significantly. In effect each team must build a new robot, although they can draw on the design, experience and insights from previous team members. Following on from the experience of Year 3 team, at the start of this season the RoboTeam Twente student group agreed to a phased three-year plan that will result in a complete redesign of the entire robot.

For ‘total football’ you need movement and control

As a team from the Netherlands it is not surprising that the RoboTeam Twente have taken a ‘total football’ mentality to the RoboCup competition. While others have exploited defensive rules, RoboTeam Twente believe movement and passing is the way to both break down defenses and provide a solid back line. To create robots with such natural fine motor control skills has proven to be a challenge, that has evolved over the four years.

The initial design of the motor driver board was relatively simple. In addition to controlling the robots four motors (one per wheel), the motor controller also delivered the power to drive the motors. This was reasonable for simple movements, but it did mean the robot was unable to traverse short distances efficiently. Clearly this had a detrimental impact on ball receiving capabilities as it was impossible to make the necessary fine adjustments to the robot’s position.

Redesigning the motor drivers

So the Year 3 team redesigned the motor control board from scratch. The same footprint was kept for the motor drivers, but now they would use external MOSFETs. To start with these were 20 V, complementary Trench MOSFETs (PMCPB5530X) housed in DFN2020-6 packages. The prototype design responded satisfactorily to low speed inputs and was able to move short distances reasonably well. All looked good until the team was ready to manufacture the entire 15-robot squad. The controller IC they used in their prototype was no longer available, and the subsequent redesign to accommodate a new controller IC resulted in the small-signal MOSFETs overheating.

Having discovered the underlying problem, a combination of design and layout issues that lead to local heating of the dual devices, the team decided to switch to six 30 V, 1.9 mΩ TrenchMOS devices in LFPAK33 (PSMN1R6-30MLH). The need for more general changes in the PCB layout to accommodate the larger footprint of the MOSFETs was outweighed by the improved passing and receiving reliability benefits the change delivered. And as these MOSFETs are rated for much higher currents, they also open the door to more powerful motors.

Switching to 24 V board net

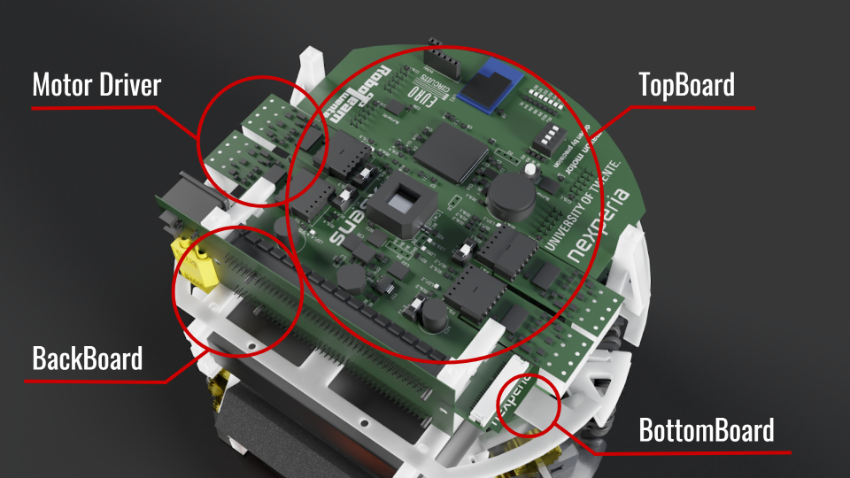

As part of the plans for the longer-term redesign, the challenge for the Year 4 team was to switch from 12 V to 24 V motors. This offers an almost two-fold increase in power and greatly contributes to the plan to improve passing and receiving capabilities. To adjust to the new motors, the robot’s batteries would have to be swapped out for 22.2 V batteries. However, that meant all four boards the team use (bottom board for power, top board for processing, motor drivers, and the interconnecting back board) would need a refresh as an absolute minimum.

Naturally one of the biggest parts of the redesign was with the bottom board as it houses the massive 450 V capacitor needed to power the robot’s kicking mechanisms. With more powerful batteries the capacitor charging circuit had to be completely overhauled. Following the redesign, the team realized they have made an error when they were unable to properly charge the capacitors. Unfortunately during the redesign a 4-bit voltage translating buffer (74LVC4T3144) thought to be a residual part from an old system on the bottom board was removed. Of course, this was actually translating the 3.3 V microcontroller signal up to the 5 V signal required by the charging circuit. It was very quickly put back in place.

Outreach program on the backburner

Since they began four years ago, with Nexperia as a key sponsor, RoboTeam Twente have been going from strength to strength. Along with creating new robots to compete in the RoboCup, the team has been slowly building up an outreach program to teach engineering and programming skills to school children. For the Year 4 (2019-2020) team the idea was do more workshops and even a larger regional or even country wide event. Unfortunately, just as with RoboCup 2020, these plans have had to be put on the backburner. However, the team are still hoping to get some workshops going during the summer. As well as take on some of the German teams in international friendly matches as soon as travel and social distancing restrictions allow.