Super-speed interfaces such as HDMI and USB have become the norm for quickly transferring lots of data, but they need dedicated and effective ESD and EMI protection.

In consumer and computing based products, super-speed interfaces have become the norm where large quantities of data need to be transferred or copied in a short timeframe, such as high-definition video and audio. All super-speed interfaces, such as HDMI 2.0 and USB 3.2, use differential data signals and operate with reduced signal levels. High data speeds, up to 20 Gbit/s, require a carefully designed PCB layout to maintain signal integrity. This challenge requires proper impedance matching to avoid unacceptable losses and reflections.

Various electromagnetic interference (EMI) aspects need to be considered especially when sensitive Wi-Fi, cellular or GPS receivers are located close to potentially radiating high-speed interfaces. As both high-speed wired lines and popular wireless standards frequently interfere in the Gigahertz range, EMI issues shouldn’t be overlooked because these can significantly affect the user experience.

Electromagnetic interference is no choking matter!

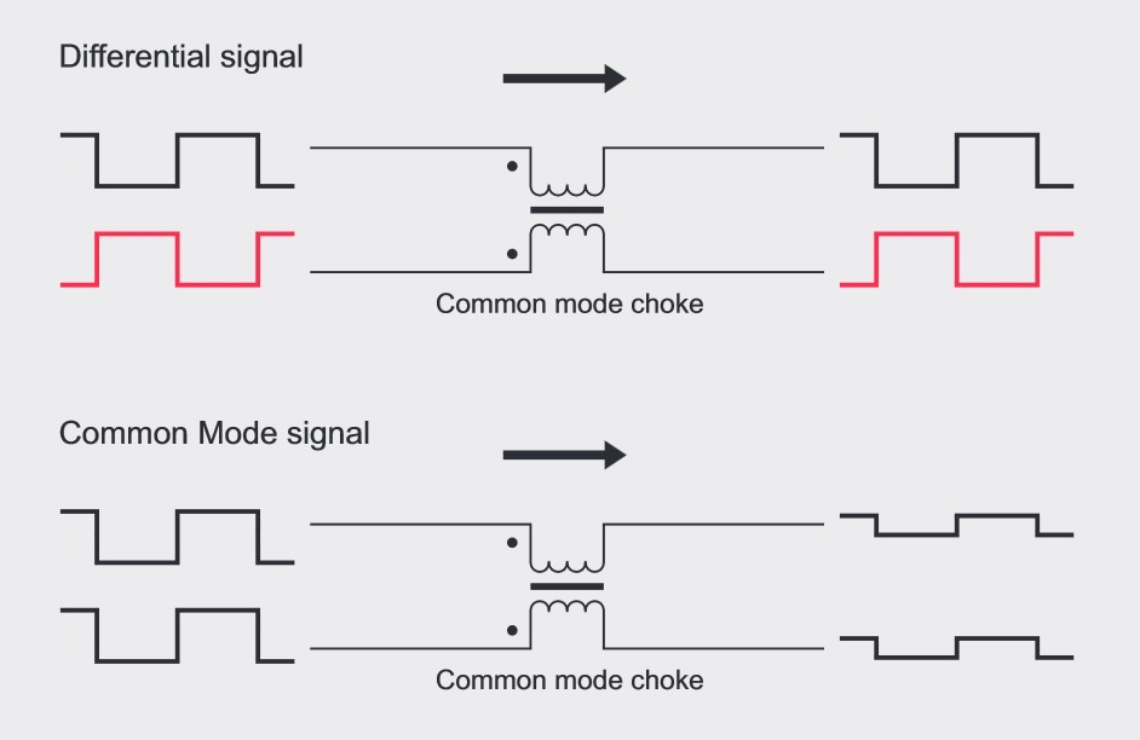

To maintain data integrity in super-speed interfaces, designers must have effective EMI filtering in place. One useful device to include is the common-mode filter (CMF) or common-mode choke (CMC), which comprises two coupled coils. When current flows in the same direction in both coils, the filter has a high impedance. Conversely, when current flows in opposite directions, the impedance is low.

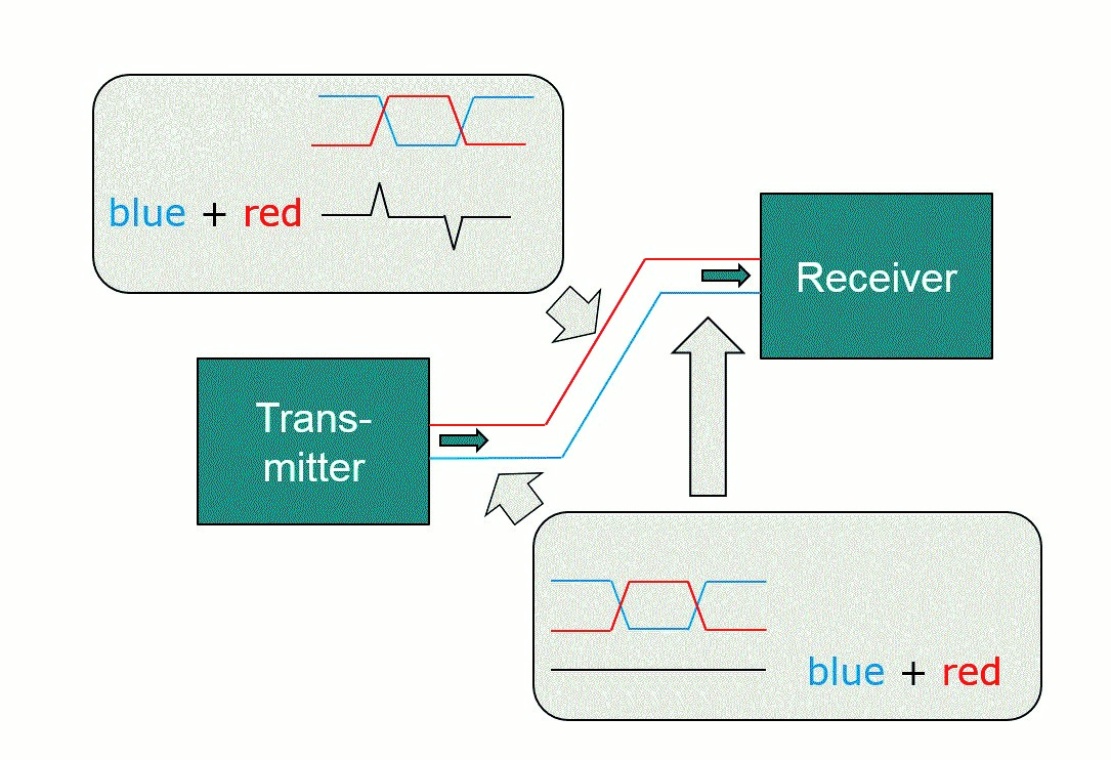

When common mode filters are applied to differential data lines, the differential part of the data carrying the information can pass. At the same time, the overlaid common mode signal content is blocked (Figure 1). Common mode noise can be generated from non-perfect transmitters, coupling of other signals, and non-symmetrical signal lines. It is created easily in the PCB layout if a signal pair changes direction and the length of the signal lines is not equal (Figure 2).

Magnetic and electrical fields are cancelled out for a differential signal in the far field, if the traces are routed within a small distance. In contrast, common mode signals can radiate into the environment and thus reduce the sensitivity of receiver blocks, especially in compact designs. For example, an activated USB 3.x interface can hinder proper reception of Wi-Fi data by a smartphone or computing device.

Protection efficiency with an integrated solution

The challenge of guarding USB and HDMI interfaces against EMI is accompanied by the need to protect them (and the systems they are connected to) against potential ESD strikes. Power delivery capability and reversible plugs in USB Type-C connectors are additional obstacles for USB interfaces. Most solutions currently employ separate devices to address each individual need, but Nexperia offers an alternative integrated approach combining CMF+ESD protection in one chip, such as the new PCMF series.

Integrating CMF and ESD protection into a single device reduces overall PCB mounting space requirements. It also prevents additional impedance mismatches in the signal traces, which can occur when using separate parts. PCMF solutions from Nexperia deliver optimal robustness and low clamping while also filtering EMI that could interfere with both 2.4 GHz and 5 GHz channels.

These effective two-in-one solutions are helpful for designers who prefer to choose whether an EMI filter is needed at a later stage of the design process. Our PCMF types are footprint-compatible with several PESD types for ESD-only protection, so the ESD-only and PCMF solution can be realized on the same PCB layout. This way any unused CMF footprints don’t need to be bridged with resistors as required in conventional designs, further simplifying overall design and assembly.

To get a deeper understanding of EMI and ESD protection, check out our ESD Application Handbook which provides an in-depth exploration of all the facets of ESD characteristics, design, testing and further information about interfaces & applications.