Today’s designs face significantly greater pressures than ever before, in terms of power density, space and dissipation. Yet when it comes to power diodes we have relied on SMA / SMB / SMC rectifier packages for almost 30 years. To efficiently meet today’s requirements, we need package options that deliver on miniaturization while keeping the same power handling capability. That is exactly where Nexperia’s clip-bonded FlatPower (CFP) packages come in.

For the past three decades or so SMA / SMB / SMC (SMx) packages have been the industry standard for power rectifier diodes. But from an application perspective there has been a lot of changes during that time. One key change has been the continuous increase of the power density. This can clearly be highlighted by the much higher PCB component density we see in today’s automotive systems. As the number of engine control units (ECU) in modern cars has reduced, the number of functions each ECU controls has increased. The resulting demand for miniaturization while maintaining power handling capability has clearly pushed beyond the limits of classic SMx packages.

A modern housing for a classic challenge

So, while SMx packages have played a critical role for the last three decades designers are increasingly demanding they are replaced by package options that meet the requirements of today’s applications in terms of power density and space-savings. Nexperia’s clip-bonded FlatPower (CFP) packaged Schottky rectifier portfolio offers the most efficient solutions to address power handling and thermal requirements while delivering significant space and height savings.

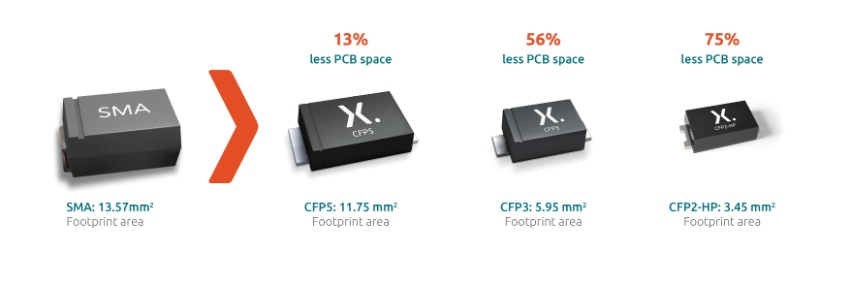

For example, using a CFP3 package instead of the SMA package can result in PCB space savings of up to 56%. The larger SMB package can be replaced by a CFP5 package with a 38% saving. And the CFP15B, the modern counterpart of the SMC, helps shrink the footprint by 40%. All three modern equivalents also come with a much lower package profile, reducing the height of the package by up to 50%.

No thermal compromises

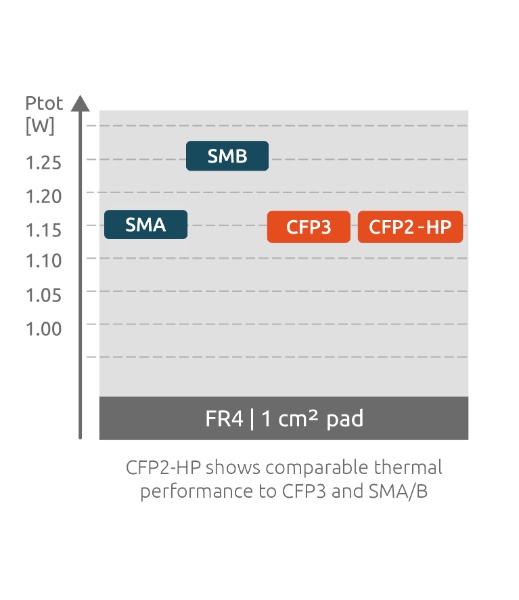

Of course, while miniaturization is crucial to meeting modern design challenges, this cannot be at the expense of power handling capability. That means any new package must dissipate at least the same amount of power even with a much smaller footprint. Measurements show that CFP packages offer a similar power handling capability as their much bulkier SMx counterparts – as highlighted by the diagram below showing total dissipated power for the different packages on various PCB types with an ambient temperature of 25 °C.

Schottky and Fast Recovery

In addition to the benefits of the CFP package, Nexperia also offers a growing range of rectifiers with over 100 devices already available. These include our silicon-based Schottky and Fast recovery diodes, ideal for example as reverse polarity protection or freewheeling diodes in DC/DC converters.