In 2024, Nexperia introduced integrated ideal diodes to its power portfolio with the automotive grade NID5100-Q100 and the commercial grade NID5100 for use in demanding environments. These devices, which are housed in the thermally optimized TSSOP6/SOT363-2 leaded plastic package, have the industry’s lowest forward voltage drop (VF) and are designed for use in 1.2 to 5.5 V systems, while supporting up to 1.5A of continuous current. Nexperia recently added to its ideal diode offerings with the NID1100, another low VF integrated device which has been released in the popular SOT753 package.

This blog explores why ideal diodes can be a better fit to traditional Schottky diodes for redundant

power supply applications. It also highlights how the features of the NID1100 make it well-suited for a

wide range of industrial applications, such as smart meters and industrial PLCs, as well as commercial

products like smart thermostats, remote controllers, and smoke detectors. (Figure 1)

Why Ideal diodes are better than Schottky diodes for protecting redundant power supplies

When designing a system with redundant power supplies, such as devices with a mains power supply and backup battery, a common approach has been to use traditional Schottky diodes to facilitate power path OR-ing (connecting supplies in parallel). The purpose of the Schottky diode is to prevent potentially damaging reverse current from flowing into the redundant power source while the primary source is in use. While Schottkys are inexpensive and have lower VF than standard diodes, this value is still not inconsiderable (up to 0.5 V), meaning power loss in the form of heat is wasted as current flows through the device. Schottky diodes also have high reverse leakage current, which can negatively impact backup battery life over time. In contrast, ideal diodes offer an efficient alternative by minimizing the VF drop and the reverse leakage current observed in conventional diode devices.

NID1100 ideal diode offers several advantages when OR-ing power supplies

Nexperia’s NID1100 (Figure 2) is an integrated ideal diode capable of replacing traditional diodes in low voltage systems, which are unable to tolerate the high voltage drops of conventional Schottky diodes. This device is designed for 1.5 V to 5.5 V systems and is rated for up to 1 A of continuous current. It regulates the voltage between the input (IN) and output (OUT) pins, resulting in a maximum VF of only 120 mV (for Vin= 3.6 V and 1 A load current). For lower forward currents, the VF of the NID1000 is up to an order of magnitude lower than similarly rated Schottky diodes, resulting in considerable power savings and less heat dissipation.

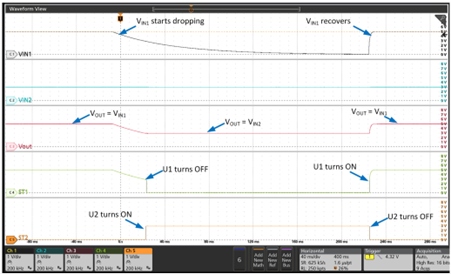

The enable (EN) pin on the NID1100 determines the operating mode - when EN is low, the NID1100 blocks voltages in both the forward and reverse directions similar to a load switch. When EN is high and the input voltage is higher than the output voltage, the inrush current control feature of the NID1100 ensures it starts up in a controlled manner. Unlike conventional Schottky diodes, ideal diodes such as the NID1100 offer additional features that are not possible with traditional diodes, including short circuit and over-temperature protection, which enhance system robustness. If a condition arises whereby the voltage at the OUT pin becomes higher than IN, the NID1100 stops conducting, thereby providing added robustness to the power path.

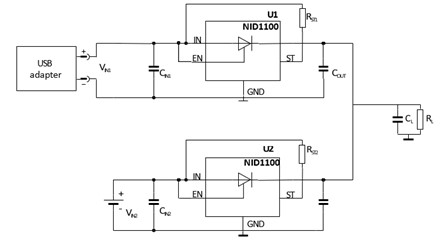

While NID1100 ideal diodes will most commonly be deployed in dual supply systems to switch seamlessly between power supplies (Figure 3), for added design flexibility, other power OR-ing configurations are also supported, including using these ICs alongside conventional Schottky diodes or with an external PMOS. The NID1100 ideal diode is available in a standard SOT753 (SC-74A) package and operates over a junction temperature range of –40 °C to 125 °C. Figure 1 Using two NID1100 ideal diodes for OR-ing two power supplies. Conclusion Compared to using Schottky diodes for power path OR-ing, Nexperia’s NID1100 ideal diode

Figure 3: Using two NID1100 ideal diodes for OR-ing two power supplies.

Conclusion

Compared to using Schottky diodes for power path OR-ing, Nexperia’s NID1100 ideal diode offers a more power efficient and cost-effective solution that brings the benefits of additional protection features for improved robustness. The NID1100 can also be easily combined with other components in Nexperia’s portfolio, including e-fuses, load switches and DC-DC converters to create a complete power chain for various applications and streamline Bill of Materials (BOM).