Industrial PSUs including datacenters come in all shapes and sizes but one thing they have in common is the need to be efficient, safe and stable. Since its introduction, 80 PLUS certification has become key for many industrial PSUs given their need for 24/7 efficiency, across a range of loadings. To make PSUs more efficient, designers of 80 PLUS® Titanium PSUs are now looking to 650 V GaN FETs to enable smaller, faster, cooler, lighter systems, with lower overall system cost.

Efficient power use is a key industrial challenge and a driver for innovation. Societal pressure, the EU Eco-design Directive and Energy Labelling Regulation demand increased efficiencies for a wide range of industrial power supply units (PSUs). In communications, servers and industrial infrastructure sectors, power conversion efficiency and power density are critical. For companies operating high-load 24/7 systems, every bit of efficiency gain can have a significant impact on operating cost.

So, while 80 PLUS Bronze and Gold efficiencies are normally good enough for consumer devices, the added efficiency that 80 PLUS Platinum and Titanium PSUs bring can result in significant power and therefore financial savings. More than that regulations for single output PSUs and multi output PSUs require ever greater efficiencies. The requirement for single and multi output PSUs was to respectively achieve 80 PLUS Platinum and 80 PLUS Gold by 2019. This has been raised to 80 PLUS Titanium for single output PSUs and 80 PLUS Platinum for multi output PSUs by 2023, with both single and multi output PSUs needing to be 80 PLUS Titanium rated by 2026.

Optimizing converter efficiency with Nexperia GaN FETs

Nexperia’s GaN FETs help PSU manufacturers drive up Titanium PSU efficiency and power density while also making them more cost-effective. The first element is better switching performance, due to a lower Qrr and fast current voltage transitions that reduces switching losses and boosts overall system efficiency. Improved system efficiency has the secondary effect of reducing requirements for expensive cooling systems and the related operating costs in closed environments. And more efficient systems can also be smaller and lighter, increasing the power density of the design.

Our cascode technology is another element that helps achieve higher efficiency and more robust PSU designs. Importantly it means our GaN FETs do not need complex and specialized gate drivers. In fact, with a high threshold voltage of 4 V and a 0-to-12 V drive voltage, they can use standard inexpensive gate drivers. Given their lower losses in reverse conduction mode due to lower Vsd, they allow more relaxed deadtime designs and higher frequency operation. Importantly for industrial applications with the inherent +/-20V gate oxide and transient overvoltage capability they are immune to gate bounce and transient spikes, resulting in more robust designs.

The positive impact on 80 PLUS Titanium PSUs

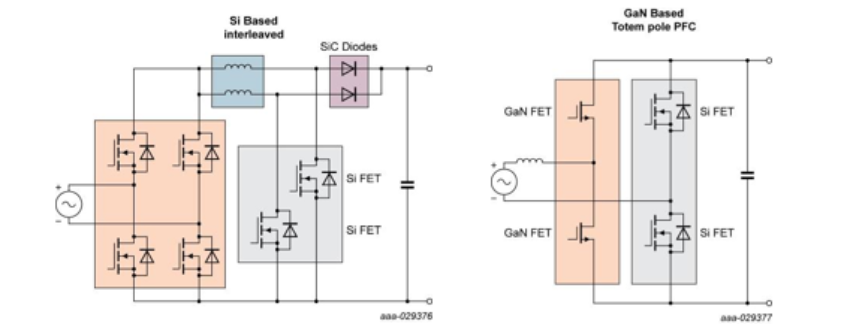

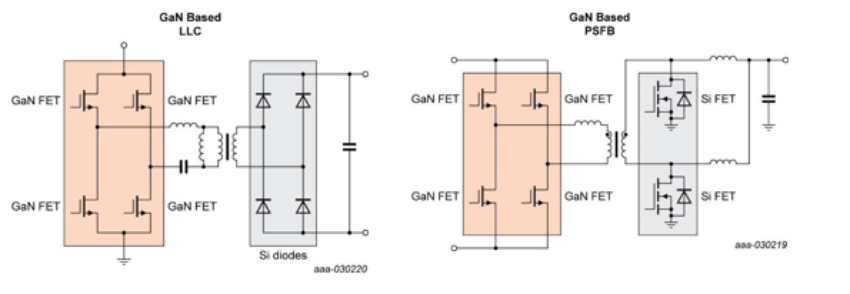

What all does this mean from a PSU application point of view? The two topologies where Nexperia GaN FETs enable all the above system benefits are AC-DC PFC and DC-DC LLC or Phase-Shifted Full Bridge (PSFB).

Let’s compare a Si-based PFC to a GaN-based bridgeless totem pole PFC for a 2-3 kW power supply. The Si interleaved topology can only approach the efficiency of the GaN totem pole if an active bridge is used. As can be seen in the circuit diagrams, the totem pole architecture using GaN FETs allows for a significant component count reduction (inductors, diodes and MOSFETs) and the simplicity in design extends to reducing magnetics and a smaller EMI filter. The potential system BoM savings can be as high as 30%, while also providing increased front-end efficiency.

|

Parameter |

Interleaved PFC |

Bridgeless Totem Pole PFC |

|

Efficiency |

98.5 % |

98.7 % to 99.1 % |

|

Total cost of PFC |

+ 15-40% |

- |

When it comes to DC-DC conversion, GaN FETs can also be used in a range of configurations including LLC or Phase-Shifted Full Bridge (PSFB). The lower current and lower flux swing leads to lower magnetic loss and faster transition. For LLC designs that means a lower RMS current, while for PSFB designs a wider ZVS range in light load conditions.

Nexperia’s latest GaN device

Of course, as we know from silicon MOSFETs one way to maximize efficiency is to drive down RDS(on). The first device in our GaN portfolio, the GAN063-650WSA, is a 50 mOHm device capable of addressing 1-3 kW applications. Our new H2 GaN technology brings several improvements compared to our H1 GaN technology, including optimizing dynamic parameters (Qoss/Coss) which has resulted in even better switching performance. So our new H2-based GAN041-650WSB, which has a typical RDS(on) of just 35 mOhms, can address higher power level systems, in general above 3 kW.