Insulated Gate Bipolar Transistors (IGBTs) have been around for some time, in fact General Electric (GE) released the first IGBT product back in June 1983. Since then, IGBTs have become a staple component of medium and high-voltage (> 200 V) applications, including Heating, Ventilation, and Air Conditioning (HVAC) systems as well as high-current applications like electric welding and induction heating. With the increasing adoption of solar panels, EV-chargers and industrial servo motors, the requirement for high-voltage solutions is rising. To meet these industry demands and complement our growing high-voltage technology portfolio (GaN and SiC), Nexperia is introducing a range of IGBT families.

One of the biggest changes the electronics market is seeing is the growth in system electrification and renewable energy. That has spurred significant growth in power-efficient electronic systems like electric vehicle charging stations, solar power installations, and more recently heat pumps. At the same time, with the Smart Factory and Industry 4.0 an increasing number of robots are being used, particularly when it comes to repetitive heavy lifting operations where more powerful servo motors are needed. The result is the market for IGBTs is expected to almost double by 2030 (according to various market research reports).

IGBTs have evolved to meet today’s demands

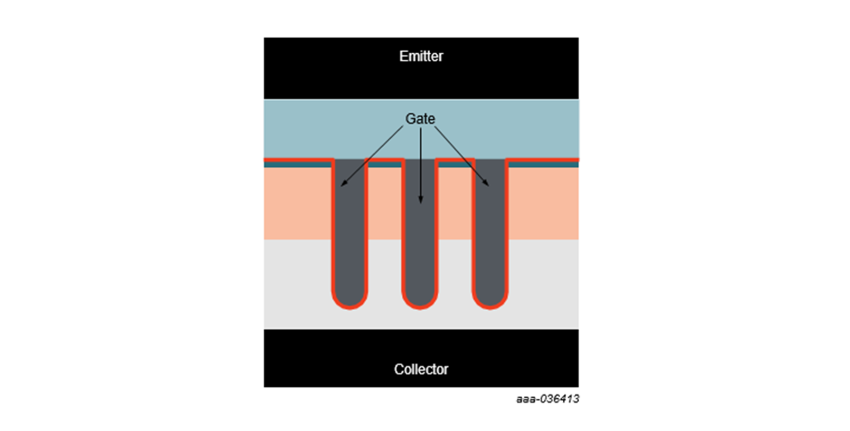

Of course, in the 40 years since the first IGBT product was released the technology has evolved significantly. No longer are the simple DMOS structures of the 1980s in use, instead todays IGBTs use carrier-stored trench gate (CSTG) technology. Nexperia employs CSTG with an advanced third field stop (FS) construction and multiple metal layers deposited on the wafer backside. As well as enabling both high power density and high reliability, this fabrication process achieves the best trade-off between device conduction and switching performance.

A proven portfolio and partner

With our 650 V family designers can initially choose between Nexperia’s medium speed (M3) and high speed (H3) discrete IGBTs housed in the TO-247-3L. The M3 family (below 20 kHz) is optimized for low conduction losses while maintaining minimal switching losses and offering a 5 µs short-circuit capability. Whereas the H3 family (from 20 to 50 kHz) prioritizes low switching losses with minimal conduction losses. Achieving the best trade-off between device conduction and switching performance has been a key focus for Nexperia to deliver high ruggedness reliability (passed HV-H3TRB – High Voltage-High Humidity High Temperature Reverse Bias) and enhance inverter power density at temperatures up to 175 °C. And of course, as a dedicated supplier of essential semiconductors, Nexperia has the infrastructure to deliver high-quality products at scale.

Discover more about Nexperia’s initial portfolio of 650 V IGBTs and download their datasheets.