36 V lithium-ion battery powered tools and outdoor power equipment have become increasingly commonplace. They offer a great mix of power and battery life, while still being relatively light and easy to use. But with higher energy density comes the need for efficient battery isolation. Nexperia’s new 50/55 V Application Specific MOSFETs offer the necessary Safe Operating Area (SOA) and robustness, while providing significantly improved efficiency and the highest power rating. That can be in both a 5*6 mm footprint or an 8*8 mm package, offering improved performance against D2PAK parts.

The rise of cordless, battery powered tools and outdoor power equipment has been dramatic over the last few years. One of the key drivers in this move has been the availability of long-lasting, 10-cell 36 V lithium-ion battery packs. Offering high energy density, these batteries are ideal for professional tools but also for traditionally corded or even engine driven outdoor power equipment such as chainsaws and lawn mowers. However, with the rise in energy density comes a greater need for efficient battery isolation.

To handle any significant discharge in a controlled manner until the battery is safely isolated and the system switched-off, requires an extremely robust and thermally efficient MOSFET. Given standard MOSFET voltage ratings, for 36 V batteries this has led designers to use 60 V MOSFETs. However, for a nominal 36 V rating a 50 V or 55 V MOSFET is ideal. And reducing the MOSFET voltage rating, opens the door to optimizing SOA, ID rating and avalanche capability to enhance overall safety and efficiency.

Maintaining Safe Operating Area is vital

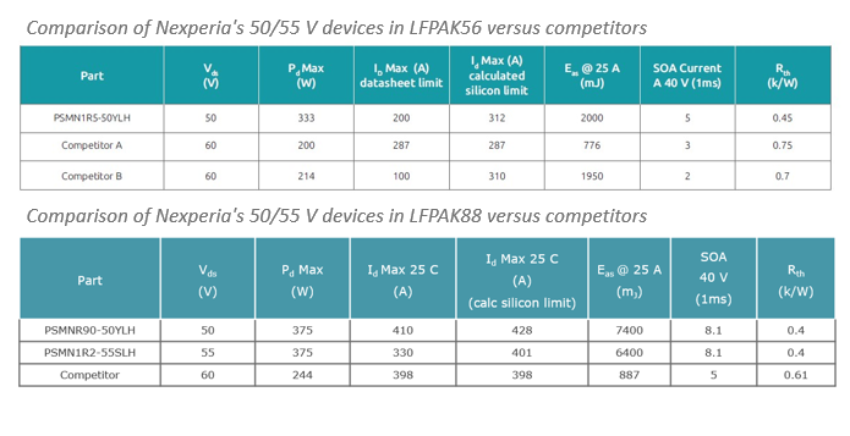

Under fault situations, a battery isolation MOSFET normally goes into linear mode due to voltages being developed across circuit inductance at high current when the fault causes a deep discharge. So, maintaining a strong SOA is vital. Nexperia’s MOSFET technology lends itself to superior SOA and with the 50/55 V ASFETs we have optimized the performance for discharges between 1 and 10 ms. That means for example the 5*6 mm PSMN1R5-50YLH can handle a linear mode discharge of up to 5 A @ 40 V for 1 ms and the 8*8 mm PSMNR90-50SLH can handle up to 8.1 A under the same conditions.

Optimizing avalanche capability

Battery isolation MOSFETs are usually positioned remotely from the load and can be subjected to unclamped inductive spiking (UIS). By optimising the VDS voltage (50 V) closer to the battery voltage (36 V) helps reduce the energy dissipated by at least 20% and avoid potential failure when compared to a 60 VDS part. But given the ruggedness of the typical applications, then avalanche events are potentially quite common. Nexperia’s PSMN1R5-50YLH has a single pulse avalanche rating (EAS) @ 25 A of 2000 mJ and can handle such events repeatedly, while the PSMNR90-50SLH goes up to 7400 mJ.

Expanding an already proven portfolio

With the release of dedicated 50/55 V ASFETs, Nexperia is the first to specifically target 36 V battery systems with a 50 V rated MOSFET. Optimizing for SOA, ID rating and avalanche capability while maintaining good RDS(on), provides designers with an extremely robust battery isolation solution. With the choice of a DC current rating of 200 A and a calculated silicon limit of 312 A (LFPAK56) or 410 A and a calculated silicon limit of 425 A (LFPAK88), this industry leading performance builds on Nexperia’s portfolio of proven ASFETs for Battery Isolation and 50/55 V for 36 V DC motors.