High-power LED strings, such as those used in car headlights, require a constant current that remains stable regardless of changes in ambient temperature and input voltage fluctuations. This ensures a constant brightness level in the LED string, helping to increase its operating lifetime. There are several solutions to drive power LEDs. A well-established discrete approach uses a combination of a precision shunt regulator and power bipolar transistors arranged in a current sink configuration.

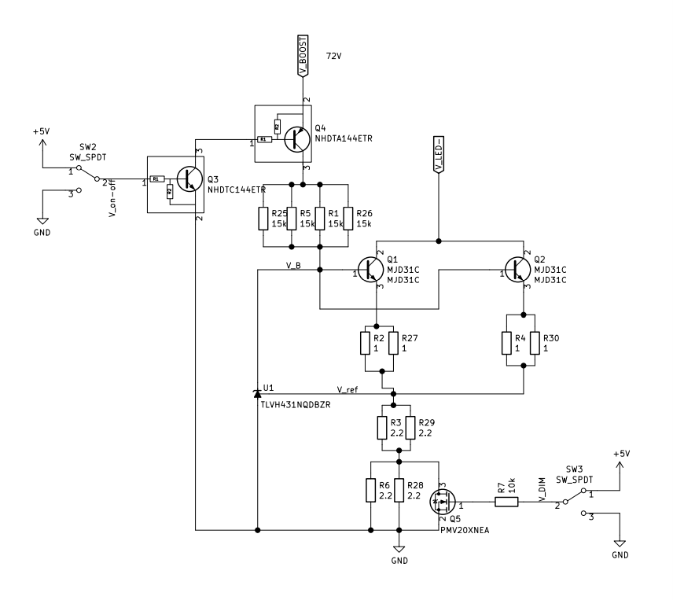

Linear regulation is used at the output stage of a boost converter to up-convert the 24 V supply voltage to 72 V, and provide the high voltage required to power two parallel LED strings. The base terminals of two 100 V NPN transistors connected in parallel are controlled using an adjustable precision shunt regulator to let them operate in the linear region. The resistor in the feedback loop determines the load current so that the total current consumption in the brightest operating mode is 1 A.

Stable and robust operation through BJTs

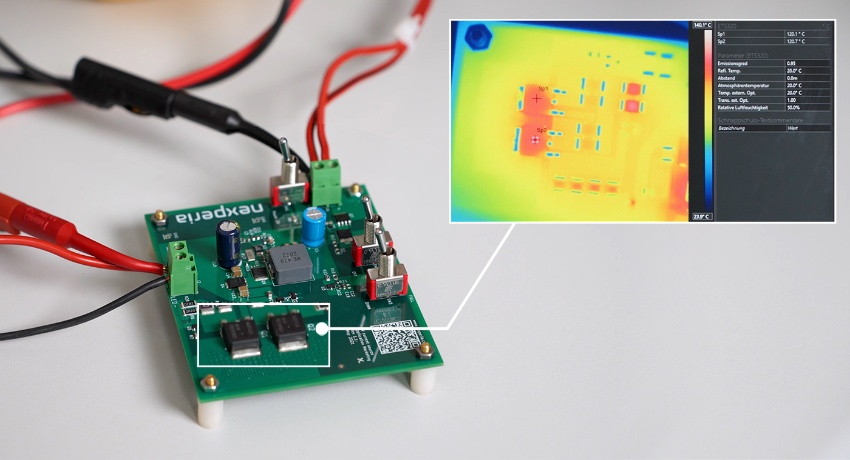

By inspecting the circuit through an IR camera (Figure 2), it can be seen that even in the brightest setting, the BJT’s temperature stays well below the maximum allowable upper limit. This discrete approach also provides an additional degree of freedom for thermal management on the PCB compared to an integrated solution. The robustness of this solution can be demonstrated by the fact that the brightness and temperature of the LED string does not change when an input voltage fluctuation of 1 V is applied. Even when the ambient temperature increases to 50 °C, the circuit still operates reliably.

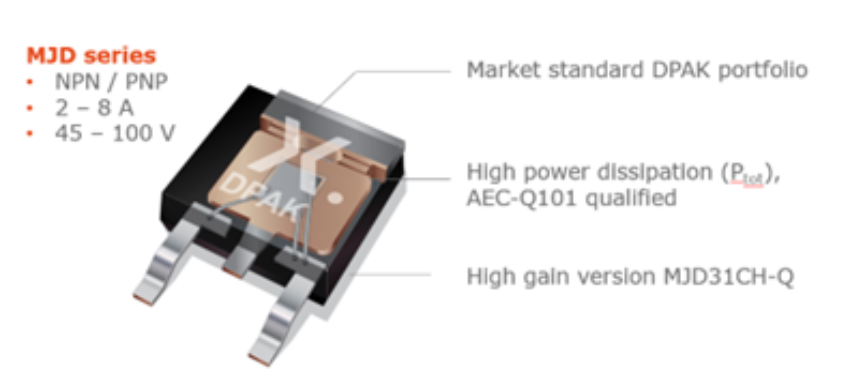

Excellent thermal performance with DPAK packaging

Nexperia’s MJD series of power bipolar transistors in DPAK packaging, which provide excellent thermal power dissipation, are very well suited for this application. This solution uses two automotive-qualified MJD31C high-power 100 V 3 A NPN bipolar transistors, but for applications that require a more precise linear regulator, the MJD31CA can be replaced by the higher-gain MJD31CH-Q.

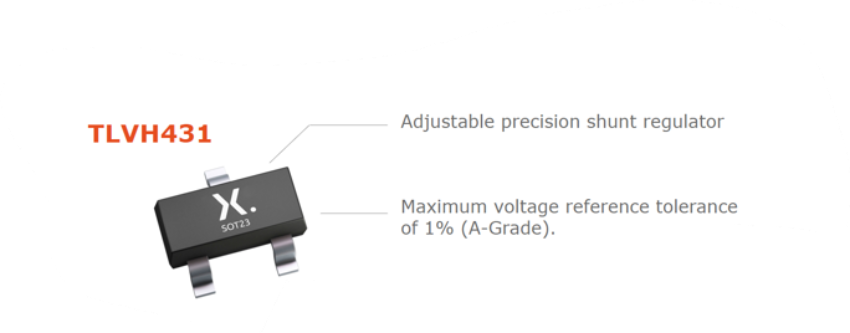

The base current of these devices is controlled by the TLVH431 A-Grade precision shunt regulator with a maximum current sink capability of 70 mA. An additional benefit of linear regulation in the output stage is that no additional electromagnetic interference (EMI) is introduced – a key consideration in the automotive environment.

Sustainable operation

Achieving robust and sustainable operation in high-power LED strings requires a current that remains stable regardless of temperature and input voltage fluctuations. A discrete high-voltage current sink topology using Nexperia’s MJD series power bipolar transistors and a precision TLVH shunt regulator ensures constant LED brightness in a straightforward solution that comes at the best price-performance ratio.

For more information please visit: www.nexperia.com/MJD